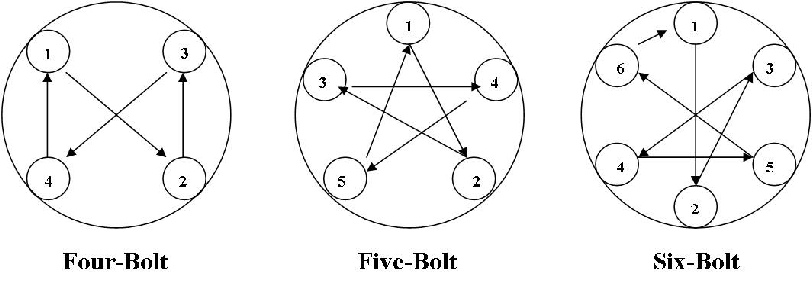

1. When fitting the road wheel to the hub/drum assembly, the wheel nuts should be tightened in star sequence (See Figure 1 below) to the correct tension for the size of wheel nut with an accurate tension wrench. (See Table 1 below).

2. Place the first nut on a stud and tighten by hand. Proceed to the next stud in the appropriate sequence as illustrated in Figure 1, put on the next nut and tighten by hand. Continue until all the nuts are tight enough to secure the wheel in place. Repeat the procedure with a tension wrench and tension each nut as appropriate, in the same sequence, to the appropriate tension for the size nut/stud.

Do not use an impact tool ('rattle gun' or similar) to tighten wheel nuts.

Do not over or under tension wheel nuts.

Stud Size (UNF) Tension (Metric) Tension (Imperial)

7/16" 110 Nm 80 ft/lbs

1/2" 125 Nm 90 ft/lbs

9/16" 140 Nm 100 ft/lbs

A. Check tyre pressure is as per indicated on side wall of tyre or on V.I.N plate, never run on un-inflated tyres or over inflated tyres.

3. Check that the road wheel rotates freely but firmly with no sideways movement. If the bearing retainer nut is too tight or too loose (when tightening the bearing retainer nut, tightening the nut till it stops do not over tighten or you will damage the bearing surface them turn back one full castellation this should line up with the hole for the split pin) it will significantly reduce the life of the axle, bearing and brake assembly. Check the Bearing Fitting and Adjustment Guide and Brake Adjustment Guide from the relevant manufacturer for detailed instructions on adjusting bearings and brakes for best results.

4. Check and confirm that the nuts on the axle retaining U-bolts are correctly tensioned.